Microsoft Dynamics 365 Business Central

Supply Chain Management

Optimize your supply chains and defy global crises

ERP systems with their digital procurement processes offer enormous potential for automation and give your purchasing scope for modern supply chain management. The system takes over the routine tasks such as disposition, order processing, invoice verification and immediately draws your attention to any discrepancies. Especially in times of disrupted supply chains, this gives your purchasing time and energy for the essential issues: counteracting the effects of delivery delays as sustainably as possible.

Procurement management simply and automatically: from scheduling to supplier invoices

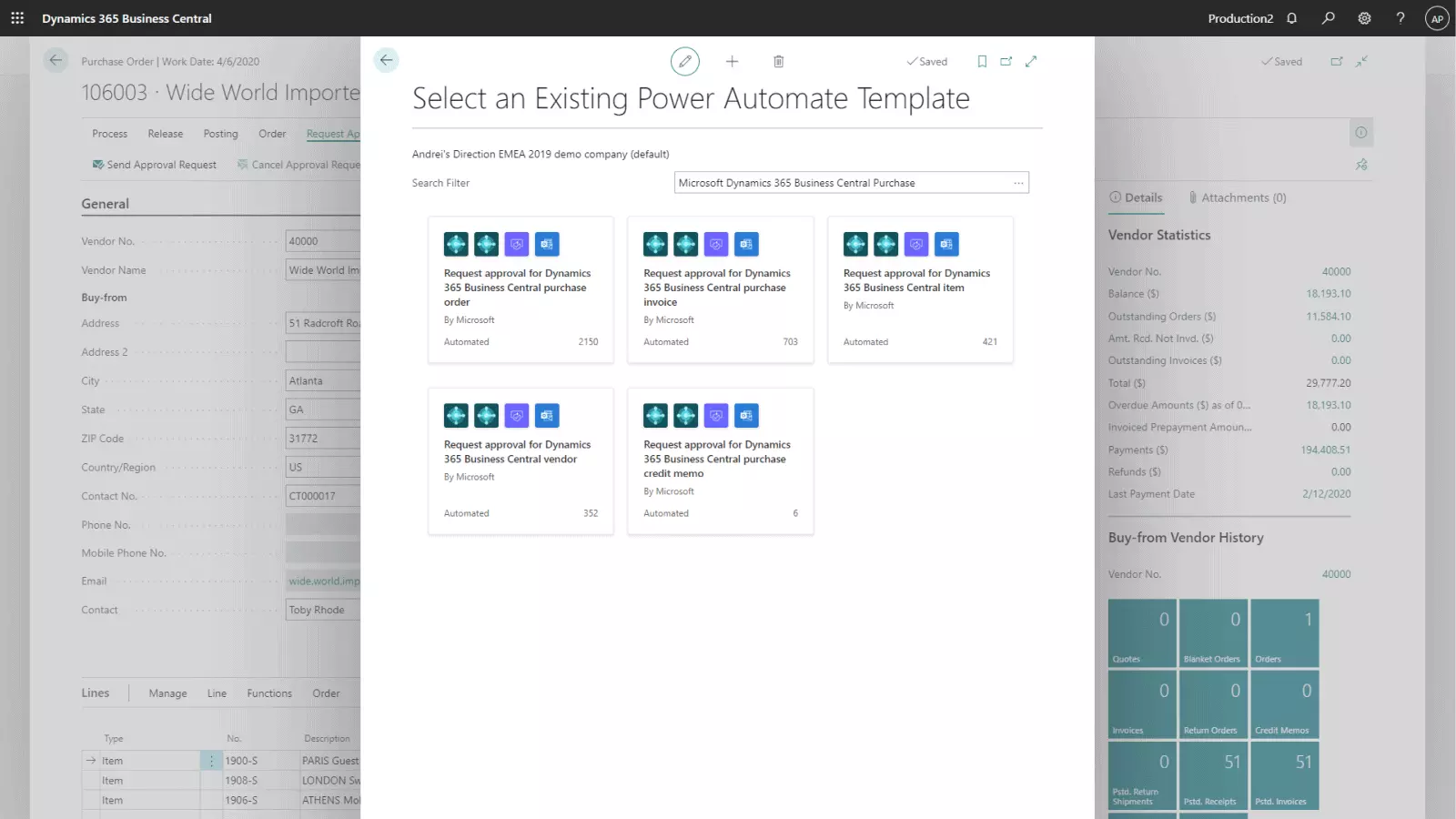

In addition, you can with Microsoft Dynamics 365 Business Central Network your delivery processes with your business partners: Inquiries, orders as well as your deliveries can be transmitted digitally via the respective communication methods. You receive offers, order confirmations, shipping notifications and invoices directly in the system. Here, too, the system helps with automatic processes and immediately shows deviations, for example from delivery dates. Thanks to the workflow controls, the information also comes directly to the "virtual" desk of the responsible employee.

- Transparent internal and external supply chains including item tracking

- Digital automated order processing

- Summary of items and quantities at supplier level

- Automatic invoice verification

- Analysis of delivery date, quantity and price deviations

Get to know Business Central

- Transparent supply chains

- Purchasing and Procurement

- logistics and warehousing

- shipping and export

- Supplier management

Do you have any questions or would you like to talk about a project?

The heart of merchandise management: material requirements planning - disposition

- Disposition of merchandise from sales orders

- Material requirements planning for production orders by BOM explosion

- Automated calculation of order times and quantities

- Consideration of stocks such as minimum & safety stocks

- Consideration of delivery times, alternative suppliers and items

- Calculation of delivery dates for sales orders

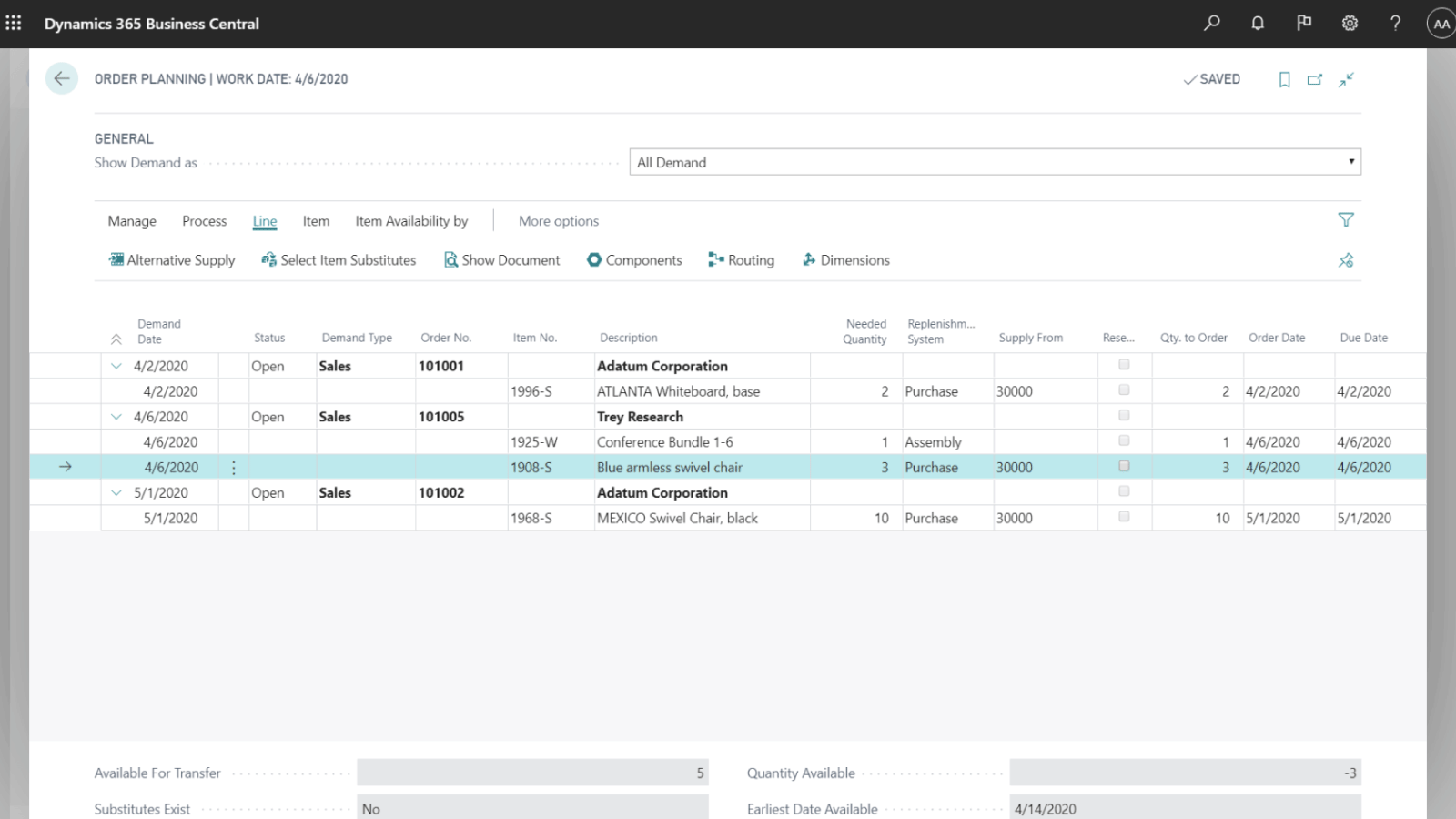

It all started with scheduling: What was a revolution in the 1970s is still the heartbeat of every ERP system today: Which (BOM) items are required for which order and in what quantity and when do they have to be delivered based on the delivery times be ordered from the respective suppliers?

Due to the changes in the world markets, material planning is more challenging than ever: minimum or safety stocks must be able to be adjusted flexibly, alternative suppliers must be included in the material requirements planning just like alternative items, so that delivery dates can be met or, in case of doubt, postponed.

Supplier management – who supplies what at what price

Since global supply chains have lost their reliability, price is no longer at the top of supplier ratings. Unrestricted delivery routes already ensure delivery times today - not only to you, but also to your customers.

The cheapest is no longer the cheapest supplier, but the one who is worth the price. With integrated digital supplier management, you can even reevaluate your suppliers on a daily basis if in doubt.

In our KUMAVISION app Vendor rating management we have expanded the standard functionalities by some essential functionalities: Using an individual points system with qualitative and quantitative evaluation criteria, you can perfect the supplier evaluation according to your own standards, carry out audits and can even evaluate your outsourcing (extended workbench).

- Establishment of your individual supplier evaluation system

- Automatic and manual ratings

- Planning and implementation of audits

- Evaluation of suppliers, individual processes and external manufacturers

Transparent inventory management from goods receipt to delivery

- Transparency of quantity and value flow

- Comprehensive mapping of the warehouse structure including storage zones and locations

- Use of a wide variety of storage strategies (chaotic warehousing/location selection, FIFO/LIFO, etc.)

- Simplification of the picking by e.g. Kumavision Split by Picking Area

- All storage and shipping documents including labels, packaging specifications, etc.

- Connection of logistics and shipping service providers

- Quality assurance in incoming and outgoing goods

- Annual inventory

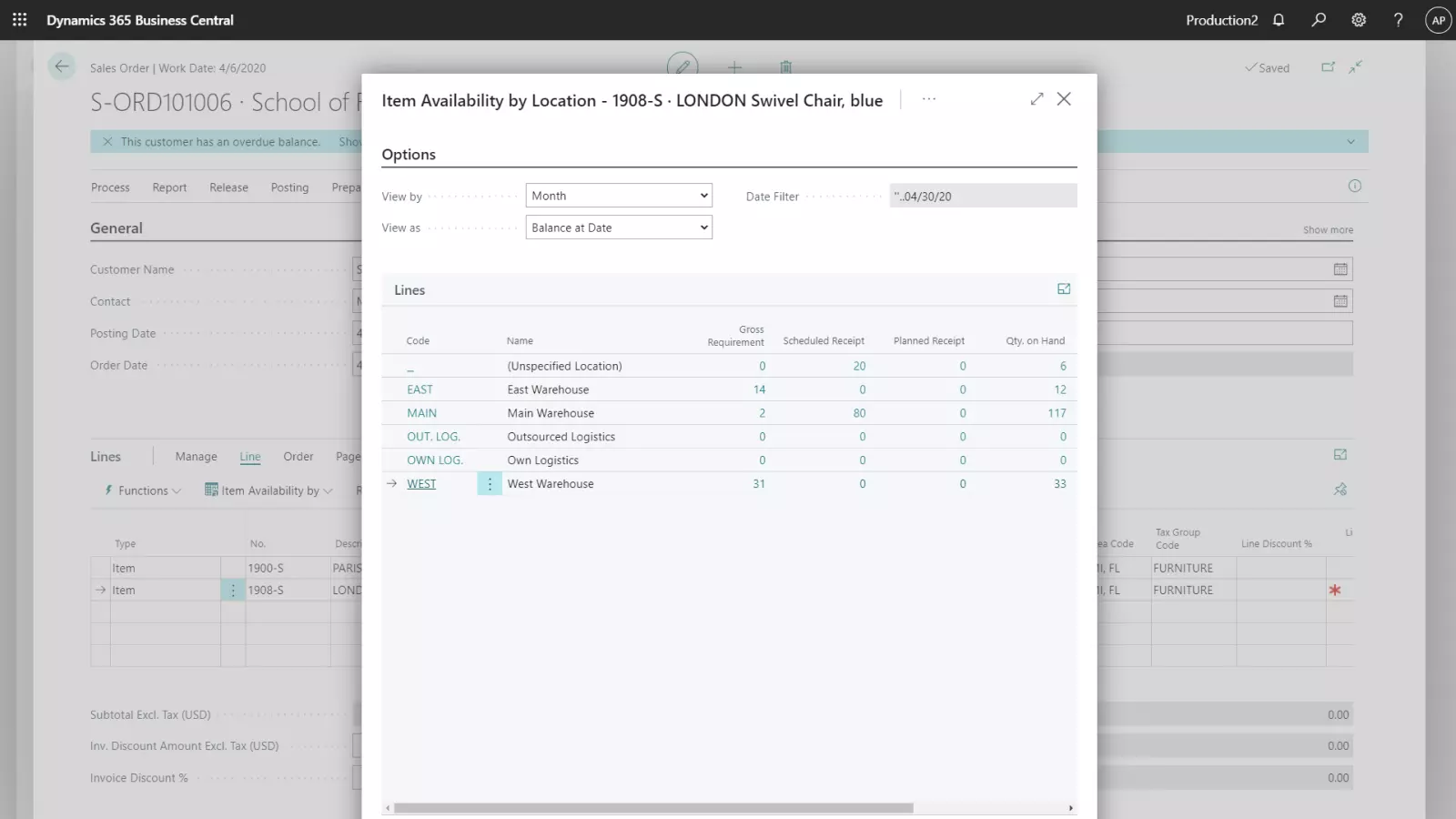

What goods are in stock and in what quantities? You no longer have to call the warehouse or check it yourself for this question. with Microsoft Dynamics 365 With Business Central, you can not only view stocks from anywhere at any time, you can also track the movements of individual items, assemblies and materials.

The prerequisite for this is the wide range of options for mapping your individual storage structure from different storage locations to storage zones and storage locations and to post the movements, for example, using modern scanner solutions. With the KUMAVISION app Replenishment & Kanban Bin you can even trigger consumption-controlled replenishment for defined storage locations, for example in production, or the relocation of items in quick picking zones.

The consistent booking of the flow of goods gives you transparency and simplifies work in various places: Article availability can be displayed directly when entering sales orders or transmitted to your online shop or B2B portals. In addition, you can connect freight forwarders and shipping service providers, automatically create the necessary shipping documents and even keep your customers up to date with delivery information and tracking codes.

Your finances will also benefit from your digital logistics: Inventory becomes much more efficient for everyone involved. Apart from that, the flow of values in the company and thus also your tied-up capital is transparent at all times during the year.